In the plastic products and packaging industry, custom-made molds are an essential part of the production process. When selecting custom molds, one of the most common concerns for businesses is: how much does custom-made mold typically cost? In fact, the price of molds is influenced by a variety of factors, and the cost can vary depending on the specific project. In this article, we will analyze the factors that affect the cost of custom molds and explain how Okoman Packaging Technology (Shanghai) Co., Ltd. can provide efficient and cost-effective mold solutions for customers.

1. Factors Affecting the Cost of Custom-Made Molds

The cost of custom molds is not fixed and is typically influenced by the following major factors:

(1) Mold Type and Complexity

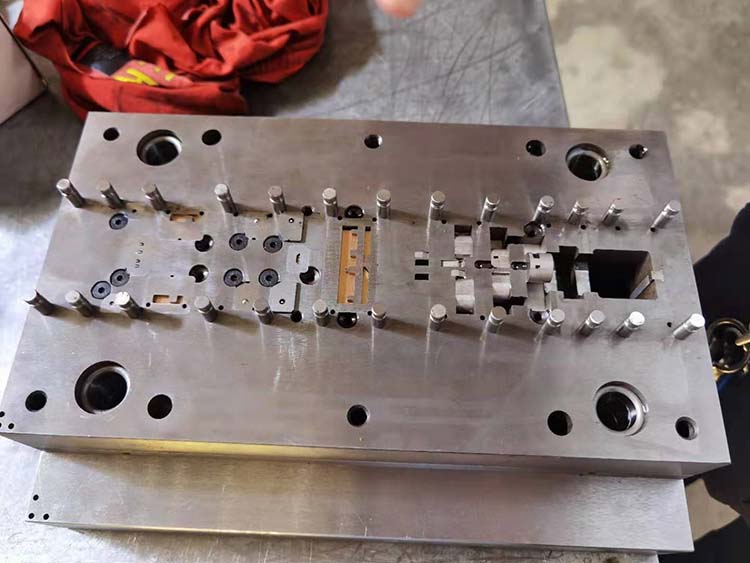

The type and complexity of the mold directly impact its price. For example, injection molds and blow molds have differences in manufacturing processes, design requirements, and precision. Simpler molds tend to be cheaper, while more complex multi-cavity molds or molds with special functions require higher technical support and fine processing, thus driving up the cost.

(2) Material Costs

The choice of material for the mold also significantly affects the price. Common mold materials include steel, aluminum alloys, and others. The cost of different materials varies, and the durability and production volume of the molds are closely related to the material chosen. Higher-quality, more durable materials generally result in higher costs.

(3) Production Quantity

The custom mold price is often proportional to the production quantity. Small batch production requires more labor, time, and material costs, so the unit price of the mold will be higher. However, for larger production volumes, the mold cost can be spread over more units, reducing the price per mold.

(4) Design and Development Difficulty

The mold design and development process involves analyzing the product structure, evaluating material properties, and optimizing the mold. If the design is complex or requires significant adjustments, it will take more time and technical expertise, which increases the overall cost.

(5) Post-Processing and Treatment

After the mold is completed, a series of post-processing steps such as surface treatment, spraying, hot stamping, vacuum plating, etc., may be required. These additional processes will add extra costs to the overall mold price.

2. Okoman Packaging Technology (Shanghai) Co., Ltd.'s Custom Mold Services

As a professional packaging technology company based in Shanghai, Okoman Packaging Technology (Shanghai) Co., Ltd. focuses on the research and development of plastic products and molds. We have a team of experienced designers and engineers who can provide high-quality and cost-effective mold solutions. Here’s what we offer:

(1) Full-Process Mold Customization Service

From mold design and development to production, Okoman provides a full-process service. We tailor the most suitable mold solutions based on your product needs to ensure optimal production efficiency and product quality.

(2) Various Mold Manufacturing Processes

Okoman has extensive experience in injection molding, blow molding, and mold development, offering customized solutions for various types of molds, including injection molds, blow molds, and die-casting molds. We cater to the needs of different industries and production scales.

(3) Excellent Technology and Quality Assurance

We use advanced production equipment and a strict quality control system to ensure every mold meets international standards. Whether it’s precision requirements or durability, we offer high-quality molds to ensure smooth production for our clients.

(4) Fast Response and Delivery

Located in Shanghai, Okoman has the advantage of fast response and delivery times. Whether it’s mold design, manufacturing, or post-processing, we can complete projects in the shortest time, helping customers improve their production efficiency.

(5) Transparent Costs and Reasonable Pricing

We offer competitive and transparent pricing for custom molds, with a detailed breakdown of the cost structure. Our pricing is reasonable, and for large batch production, we offer even more competitive rates, helping our customers reduce production costs.

3. Conclusion

The cost of custom-made molds depends on various project requirements. If you are looking for high-quality, cost-effective mold customization services, Okoman Packaging Technology (Shanghai) Co., Ltd. is your best choice. We will provide professional advice and tailor the most suitable mold solution to help your product enter the market successfully.

If you have any questions about mold customization or need a quote, feel free to contact us, and our team will be happy to assist you!