Okman Packaging Technology (Shanghai) Co., Ltd. is located in the ancient town of Nanxiang, Shanghai, just 15 kilometers from Shanghai Hongqiao Airport, offering convenient access for close cooperation with global clients. The company specializes in the research and development of plastic products and molds, with a focus on injection molding, blow molding, mold development, as well as printing, hot stamping, vacuum coating, ultrasonic welding, labeling, and assembly. In response to the growing market demand, Okman actively provides innovative and efficient solutions in the field of cold press mold customization, helping clients improve product quality and manufacturing efficiency.

What is Cold Press Molding?

Cold press molding refers to the process of shaping materials in a mold under pressure at room temperature. This method is widely used for shaping plastic, metal, and other materials. Compared to traditional hot press molds, cold press molds do not require heating of the material, which saves significant energy costs and helps achieve greater control over the product’s shape and dimensional accuracy during production.

Cold press mold customization allows businesses to create molds tailored to their specific needs, resulting in increased production efficiency and higher product quality. Okman Packaging Technology offers cold press mold customization services using professional technology and precise manufacturing equipment, ensuring that each mold meets the specific requirements of their clients.

Advantages of Cold Press Mold Customization

Increased Production Efficiency

Cold press molds allow for a more straightforward and efficient production process, as they do not require heating. By adopting advanced cold press mold technology, Okman significantly reduces production cycles and achieves mass production in a shorter time, thus lowering production costs.

Precise Control of Product Dimensions and Shape

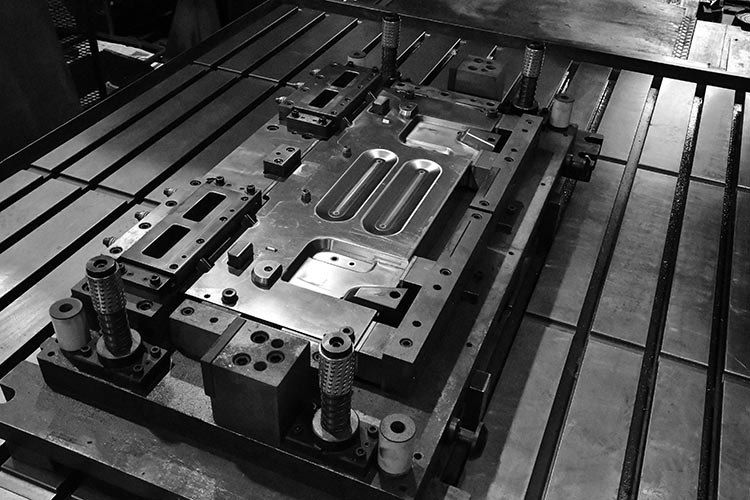

Cold press mold customization ensures that products maintain high dimensional accuracy and shape precision during the manufacturing process. This is crucial for plastic products that require high precision. Okman’s cold press molds meet strict quality standards to fulfill the diverse needs of customers.

Reduction in Material Waste

Cold press molding utilizes materials efficiently, using precise pressure control to minimize waste. This reduces both production costs and the environmental impact, contributing to more sustainable manufacturing practices.

Compatibility with Various Materials

Cold press molds can be used with a wide range of materials, including plastics and composite materials, enabling the production of diverse products. Whether for consumer goods, industrial components, or packaging containers, cold press molding meets the requirements of various industries.

Okman Packaging Technology's Cold Press Mold Customization Advantages

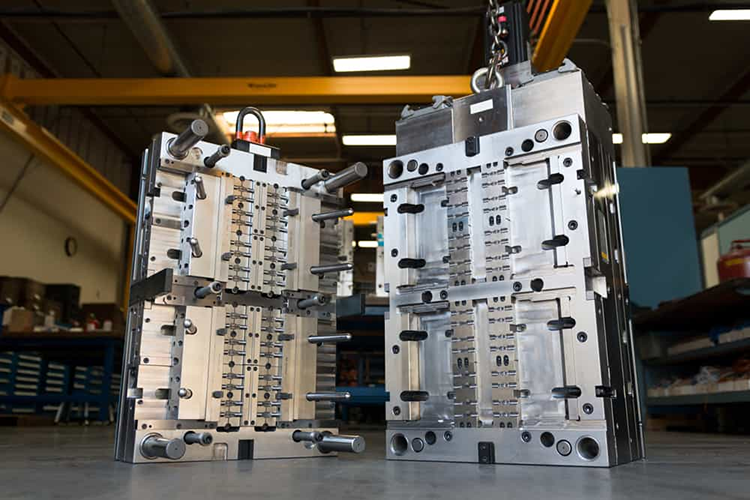

As a company specializing in plastic products and mold R&D, Okman Packaging Technology leverages its strong research and development capabilities and advanced manufacturing equipment to offer high-quality cold press mold customization services.

Advanced R&D Technology

Okman boasts an experienced R&D team capable of providing professional cold press mold design and customization services based on clients' specific requirements. Whether for complex geometric structures or high precision, Okman offers perfect solutions.Precision Mold Manufacturing

The company uses modern CNC machines and precision processing technologies to ensure that every custom cold press mold is highly accurate and stable. These molds can be applied to various production processes, including injection molding and blow molding, to meet the needs of different customers.One-Stop Service

In addition to cold press mold customization, Okman also offers a full range of product manufacturing services, including printing, hot stamping, vacuum coating, ultrasonic welding, labeling, and assembly. This enables clients to complete the entire process from design to production on a single platform.Efficient Production Management

Okman employs a comprehensive production management system and strict quality control standards to ensure that each cold press mold meets the highest quality requirements during production. Whether for small batch customization or large-scale manufacturing, Okman provides efficient and reliable delivery.

Applications of Cold Press Mold Customization

Cold press molds are widely used across various industries, particularly in the plastic products and packaging sectors. Okman Packaging Technology primarily serves the following industries:

Packaging Industry

Plastic packaging products such as containers, bottle caps, and trays require precise molds for mass production. Okman’s cold press mold customization can meet these demands and ensure high-quality results.Consumer Electronics Industry

Many electronic product components, including housings and covers, require cold press molds for precise processing. Okman offers customized mold solutions for the electronics industry to meet stringent design and quality standards.Medical Equipment Industry

Many medical products require high precision to meet regulatory standards. Okman provides cold press mold customization services to produce components that comply with these strict requirements.Automotive Industry

Automotive parts, such as dashboards and exterior components, need highly accurate molds for production. Okman has extensive experience in this field, delivering molds that meet the high standards of the automotive industry.

Conclusion

Cold press mold customization is a critical aspect of the plastic product manufacturing process, enhancing both production efficiency and product quality. Okman Packaging Technology (Shanghai) Co., Ltd., with its leading-edge technology and experienced team, provides high-quality cold press mold customization services that help clients stand out in a competitive market. Whether your needs involve personalized mold designs or large-scale production, Okman offers perfect solutions to meet your business needs.

If you are looking for professional cold press mold customization services, feel free to contact us. Okman is committed to providing you with efficient and high-quality service!