In modern manufacturing, mold opening is a crucial step in producing plastic products, especially in injection molding, blow molding, and other processes. Whether for small-batch production or large-scale manufacturing, choosing the right mold is essential. However, many businesses and customers have questions about “how much does mold opening cost?” This article will provide a detailed explanation of the cost structure, influencing factors, and advantages of Okoman Packaging Technology (Shanghai) Co., Ltd. in mold development and manufacturing.

Components of Mold Opening Costs

Mold opening costs typically consist of the following parts:

Design Fees

Mold design is the first step before mold opening. Professional mold designers usually create designs based on product requirements. The cost of design depends on the complexity and difficulty of the mold.Material Costs

The cost of materials used for the mold is another important factor affecting mold opening costs. Common materials include steel, aluminum, and copper. Steel is more expensive, so molds made for high precision and longer life typically use steel.Processing Fees

Processing costs are closely related to the complexity of the mold. More intricate molds require additional processing time and high-precision equipment, resulting in higher processing costs.Testing and Debugging Fees

Before production, molds need to be tested and debugged to ensure the product's size and quality meet the requirements. The debugging process may involve multiple adjustments and optimizations, adding to the overall cost.Quantity and Production Cycle

Small-batch production typically has higher mold opening costs because more trials and adjustments are required. For mass production, while the initial mold opening cost is higher, it becomes more economical when spread over larger quantities.

Factors Affecting Mold Opening Costs

Product Complexity

If the product design is complex, the mold structure will also be more intricate, which increases manufacturing difficulty. Complex molds require more steps and precise processing, thus raising the cost.Choice of Mold Materials

The choice of material significantly impacts mold durability, production speed, and costs. High-performance mold materials such as high-grade steel or high-hardness alloys, although more expensive, offer better precision and longevity.Mold Size and Weight

The larger and heavier the mold, the higher the cost. This is because larger molds require more material, processing time, and equipment support.Production Volume

In large-scale production, the per-unit cost of mold opening tends to be lower, as the cost is spread across more units. For small-batch customization, initial mold costs are higher, but they are suitable for quickly responding to market demands.Regional and Supplier Differences

The technical level, production costs, and market conditions vary by region and supplier, which also impacts the overall cost of mold opening.

Advantages of Okoman Packaging Technology (Shanghai) Co., Ltd. in Mold Opening

Located in Shanghai, Okoman Packaging Technology (Shanghai) Co., Ltd. specializes in plastic product and mold development, particularly in injection molding, blow molding, and mold design. Below are some of the advantages the company offers in mold opening:

Rich Technical Experience

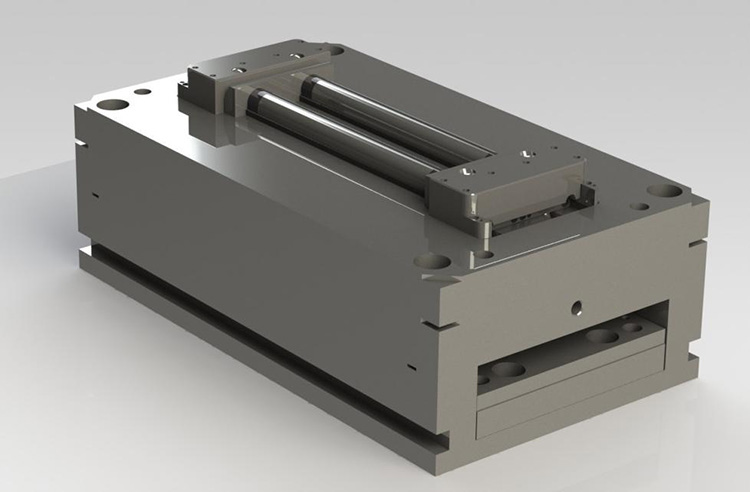

Okoman Packaging Technology has many years of experience in mold design and development, allowing the company to provide the most suitable mold solutions tailored to the specific needs of its clients.Advanced Equipment and Processes

The company uses advanced injection and blow molding equipment, as well as high-precision CNC processing machinery, to meet the design and production needs of various mold complexities.Efficient R&D Capabilities

Okoman Packaging Technology (Shanghai) Co., Ltd. has a professional R&D team capable of quickly responding to customer needs and optimizing designs, ensuring mold performance and production efficiency.One-Stop Service

Okoman provides a one-stop service from mold design, development, and manufacturing to subsequent processes like printing, hot stamping, vacuum coating, ultrasonic processing, labeling, and assembly. This helps clients reduce intermediate steps and lower overall costs.Flexible Production Models

Whether for small-batch production or large-scale manufacturing, Okoman offers flexible production options, ensuring that clients receive cost-effective mold opening services regardless of the order size.

How to Choose the Right Mold Opening Service

When choosing a mold opening service, it is essential to consider more than just the cost. The technical capability, production capacity, and service quality of the supplier are also important. Here are some key factors to consider:

Technical Ability and Experience: Choose a supplier with extensive mold design and development experience to ensure high-quality, high-precision molds.

Equipment and Processes: Advanced equipment and processes guarantee the efficiency and precision of the mold production process, minimizing production errors.

Service Capabilities: This includes mold debugging, optimization, and ongoing maintenance services. A good supplier provides comprehensive support throughout the production process.

Flexibility and Response Speed: Whether you need small-batch or mass production, the supplier's flexibility and quick response time are crucial.

Conclusion

In conclusion, mold opening costs are influenced by multiple factors, and the exact cost varies depending on the project. When selecting a mold opening service, it is essential to consider factors beyond just price, such as technical capabilities, production efficiency, and post-production support. Okoman Packaging Technology (Shanghai) Co., Ltd. is committed to providing high-quality, cost-effective mold opening services, backed by years of experience, advanced technology, and flexible production models. If you have mold opening needs, feel free to contact us. We will provide you with professional solutions and detailed consultation services.