In modern manufacturing, molds are the core tools for producing plastic products. Whether it is injection molds or blow molds, their design and quality directly impact the performance, production efficiency, and cost of the products. To ensure high-quality plastic products and efficient production, selecting the right custom mold manufacturer is crucial.

This article will provide an in-depth look at the development process and application of injection and blow molds, and with the experience of Okman Packaging Technology (Shanghai) Co., Ltd., it offers valuable insights to help you make informed decisions when customizing molds.

1. What is a Custom Mold?

A custom mold is a mold tailor-made for a specific product based on unique requirements. Unlike standard molds, custom molds are usually designed and manufactured according to the product's design, production requirements, and material characteristics. This customized approach ensures that the produced plastic products meet strict requirements in terms of shape, size, and strength.

2. Development and Application of Injection Molds

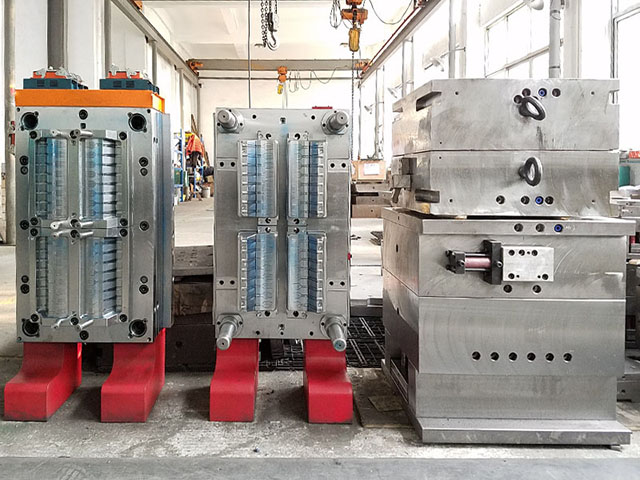

Injection molds are widely used in the production of various plastic products, especially for precision and high-volume parts. The injection molding process is efficient and precise, suitable for producing complex shapes and intricate details of plastic components.

The Development Process of Injection Molds:

Design Phase: During the design phase, a professional mold design team works closely with the client, using advanced CAD software to create detailed mold designs. This ensures that the mold's opening mechanism, cooling system, and structure are optimized.

Manufacturing Phase: Once the design is finalized, the mold manufacturing process begins. Okman Packaging Technology (Shanghai) Co., Ltd. utilizes precision CNC machines and advanced processing techniques to ensure high-precision mold production.

Trial Molding and Adjustment: After the mold is manufactured, trial molding is conducted to ensure the plastic product's shaping meets the design requirements. During this phase, Okman focuses on every detail to ensure mold stability and production efficiency.

Applications of Injection Molds:

Injection molds are commonly used in industries like electronics, automotive parts, and medical devices. Injection molding is ideal not only for mass production but also for meeting small batch, high-precision production needs.

3. Development and Application of Blow Molds

Blow molds differ from injection molds in that they are primarily used to produce hollow plastic containers. This process is typically used for products like bottles, cans, and other items with hollow structures, ideal for liquid packaging and other consumer products.

The Development Process of Blow Molds:

Design Phase: The design of blow molds needs to consider factors like plastic flowability and mold airtightness. The design team at Okman Packaging Technology (Shanghai) Co., Ltd. can tailor blow molds to meet clients' specific needs and ensure suitability for mass production.

Manufacturing and Adjustment: Manufacturing blow molds requires precise processing techniques and high-temperature resistant materials. The company employs modern manufacturing technologies to ensure the molds possess excellent high-temperature resistance and stable production capabilities.

Applications of Blow Molds:

Blow molds are widely used for producing plastic containers such as beverage bottles, cosmetic bottles, and pharmaceutical containers. This process is commonly applied in industries requiring high-volume production of precise, hollow-shaped products.

4. Key Factors to Consider When Choosing a Custom Mold Manufacturer

When selecting a custom mold manufacturer, several key factors should be considered:

Technical Expertise: A mold manufacturer with solid technical experience can offer precise designs and high-quality molds. Okman Packaging Technology (Shanghai) Co., Ltd. has extensive experience in injection and blow mold development, providing professional custom solutions tailored to various industries.

Equipment and Craftsmanship: High-precision equipment and advanced processing techniques are crucial to ensuring mold quality. Okman is equipped with state-of-the-art CNC machinery, ensuring every mold is manufactured with the highest precision.

Delivery Time and Cost: Delivery time and cost control are important considerations when selecting a manufacturer. Okman can provide flexible delivery timelines while optimizing production costs, ensuring high-quality molds within competitive pricing.

After-Sales Service: The quality of the mold and the maintenance and troubleshooting during the production process are equally important. Okman Packaging Technology provides comprehensive after-sales services, ensuring customers receive timely solutions to any issues during production.

5. Advantages of Okman Packaging Technology (Shanghai) Co., Ltd. in Custom Mold Solutions

As a professional company specializing in the research and development of plastic products and molds, Okman Packaging Technology (Shanghai) Co., Ltd. offers the following advantages in custom mold solutions:

Rich Industry Experience: With years of experience in the development of injection and blow molds, the company can provide tailored mold solutions for various industries.

Comprehensive Services: In addition to providing custom injection and blow molds, Okman also offers value-added services such as printing, hot stamping, vacuum coating, ultrasonic welding, and assembly, helping customers create end products with added value.

Efficient Production Capabilities: Located in Shanghai, Okman benefits from its strategic location, allowing for efficient service to both domestic and international clients. The company emphasizes production efficiency and guarantees on-time delivery without compromising on quality.

Custom Solutions for Clients: Okman provides personalized mold design and customization services based on the unique needs of each client, ensuring that every mold meets the specific requirements for production.

6. Future Trends in Custom Molding

As technology advances and industrial automation progresses, the custom mold industry continues to innovate. For example, the use of 3D printing technology in mold design and manufacturing is gradually transforming traditional mold-making methods, making mold development more efficient and flexible. Furthermore, environmental sustainability is becoming increasingly important in the mold industry, and molds made from recyclable materials and energy-efficient production methods are gaining market acceptance.

Conclusion

Whether it's injection molds or blow molds, selecting an experienced and technically advanced custom mold manufacturer is essential for ensuring product quality and production efficiency. Okman Packaging Technology (Shanghai) Co., Ltd., with its years of experience and comprehensive services, can provide high-quality custom molds, helping clients reduce production costs and increase product value. If you are in need of professional custom mold solutions, feel free to contact us for more information on mold development.