In modern manufacturing, the quality of molds directly affects production efficiency and product quality. Whether it’s injection molds, blow molds, or other types of molds, custom molds can be tailored to specific needs, helping companies gain a competitive edge in the market. This article will introduce the basic knowledge of custom molds and, combined with the professional services provided by Okoman Packaging Technology (Shanghai) Co., Ltd., help you better understand the importance of molds in plastic product manufacturing.

What is Custom Mold Manufacturing?

Custom mold manufacturing refers to the process of designing and creating molds based on customer requirements and product designs, suitable for specific processes (such as injection molding, blow molding, etc.). These molds are typically tailored according to factors like product shape, size, and production volume, with the goal of ensuring product precision and consistency during production.

The main advantage of custom molds is that they are designed to perfectly meet the client's specific needs, avoiding the limitations of standard molds. This results in higher production efficiency, lower costs, and improved product quality.

Common Types of Molds

1. Injection Molds

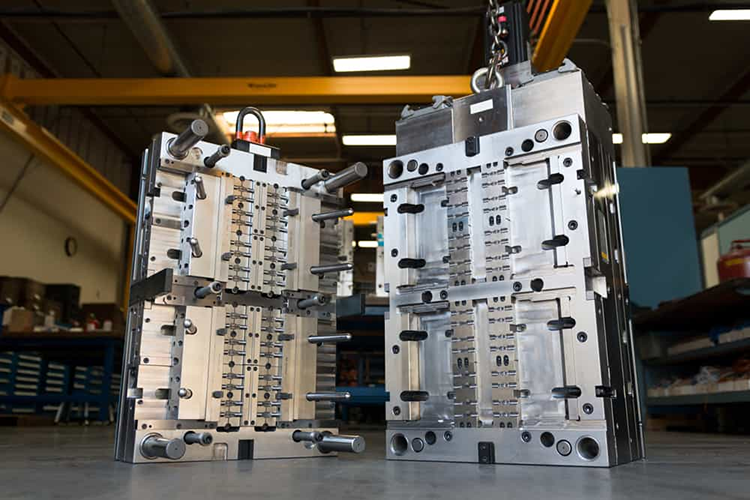

Injection molds are one of the most common types of molds used in plastic product manufacturing. In the injection molding process, melted plastic is injected into the mold cavity, and once it cools, it solidifies into the desired shape. Injection molds are widely used in industries such as home appliances, automotive, and consumer electronics, due to their ability to create complex shapes and achieve high precision.

Features of Injection Molds:

High precision, suitable for large-scale production.

Ideal for producing complex and detailed plastic parts.

Long mold life, making them suitable for mass production.

2. Blow Molds

Blow molds are primarily used for the production of hollow plastic products, such as plastic bottles, containers, and pipes. The process involves heating plastic and blowing it into a mold, forming the desired shape using air pressure. Blow molds are widely used in the packaging industry.

Features of Blow Molds:

Suitable for producing hollow or empty plastic products.

High efficiency and large-scale production, ideal for mass manufacturing.

Simple design, short production cycle.

3. Die-Casting Molds

Die-casting molds are used for metal casting, typically for aluminum, magnesium, and zinc alloy precision casting. They are ideal for creating complex metal parts and are widely used in industries such as automotive, home appliances, and electronics.

Features of Die-Casting Molds:

Suitable for precision casting of metal parts.

High precision, ideal for mass production.

Durable molds, making them suitable for long-term production.

4. Stamping Molds

Stamping molds are primarily used for sheet metal processing, commonly used in the automotive and home appliance industries. The process involves applying pressure to metal sheets to form the desired shape. Stamping molds offer high precision and production efficiency.

Features of Stamping Molds:

High efficiency and precision, ideal for mass production of metal parts.

Capable of producing complex metal parts.

High initial investment but significant long-term benefits.

Okoman Packaging Technology (Shanghai) Co., Ltd.: Professional Custom Mold Manufacturer

1. Company Overview

Okoman Packaging Technology (Shanghai) Co., Ltd. is located in the ancient town of Nanxiang, Shanghai, just 15 kilometers from Shanghai Hongqiao Airport. The company specializes in the research and development of plastic products and molds, offering a full range of services from design to production. Our main business includes injection molds, blow molds, mold development, and mold manufacturing, along with post-processing services such as printing, hot stamping, and vacuum plating.

With years of industry experience and advanced production technology, Okoman has become the preferred partner for many companies seeking custom mold manufacturing solutions.

2. Professional Custom Mold Manufacturing Services

As a professional custom mold manufacturer, Okoman Packaging Technology (Shanghai) Co., Ltd. provides comprehensive custom mold solutions. We have an experienced design team that can provide precise mold design solutions tailored to the client's needs, and our high-precision processing equipment ensures the molds meet the required specifications.

Main Services Include:

Injection Mold Customization: Providing precision injection molds based on customer plastic product requirements, ensuring high-quality injection molding.

Blow Mold Customization: Suitable for the production of hollow plastic products such as bottles and containers, helping customers achieve efficient manufacturing.

Mold Optimization and Maintenance: We offer mold maintenance and repair services to extend the mold's lifespan and ensure stable long-term production.

3. Technological Advantages

Okoman Packaging Technology (Shanghai) Co., Ltd. has significant technological advantages in mold design and manufacturing. We are equipped with advanced CNC machining equipment, EDM electrical discharge machines, precision grinders, and other devices, ensuring mold accuracy meets the highest customer standards. Additionally, our design team uses advanced CAD/CAE software for mold design and simulation analysis to optimize mold structures, ensuring production efficiency and product quality.

4. High-Quality Customer Support

At Okoman, we not only provide high-quality custom mold manufacturing services but also offer comprehensive technical support to ensure the success of your projects. Whether in the design stage or during production, we provide professional advice and solutions to ensure the smooth operation of your molds.

How to Choose the Right Custom Mold Manufacturer?

When choosing a custom mold manufacturer, businesses should focus on the following key factors:

Technical Capability: Choose a manufacturer with advanced equipment and technical support to ensure mold accuracy and quality.

Experience and Reputation: Consider the manufacturer's industry experience and customer feedback to select a reliable supplier.

Production Cycle and Delivery Time: Choose a manufacturer with a proven track record for meeting delivery deadlines.

After-Sales Service: Quality after-sales service is crucial for ensuring smooth production, including mold maintenance, repair, and technical support.

Okoman Packaging Technology (Shanghai) Co., Ltd. is your ideal partner for custom mold manufacturing with strong technical capabilities and rich industry experience.

Conclusion

Custom molds play a critical role in the production of plastic products. Whether it’s injection molds, blow molds, or other types of custom molds, choosing the right custom mold manufacturer can greatly enhance production efficiency and product quality. Okoman Packaging Technology (Shanghai) Co., Ltd., with its professional technology, extensive experience, and comprehensive services, is committed to providing high-quality custom mold solutions. If you are looking for a reliable custom mold manufacturer, Okoman is the perfect choice for your business.