In modern manufacturing, two-shot injection molding (also known as two-color injection molding) is an innovative plastic processing technology that is gradually transforming the design and manufacturing of plastic products. This technology involves injecting two different materials or colors into the same mold simultaneously, enabling the production of multi-functional, aesthetically unique plastic products. As market demand continues to grow, two-shot injection molding is being widely applied across industries, including consumer electronics, automotive parts, home appliances, and medical devices.

Okman Packaging Technology (Shanghai) Co., Ltd., a leading company specializing in plastic products and mold development, has built up significant expertise in the field of two-shot injection molding, providing efficient and precise injection molding solutions. This article will delve into the principles and advantages of two-shot injection molding, as well as the practical applications of this technology by Okman.

Basic Principles of Two-Shot Injection Molding

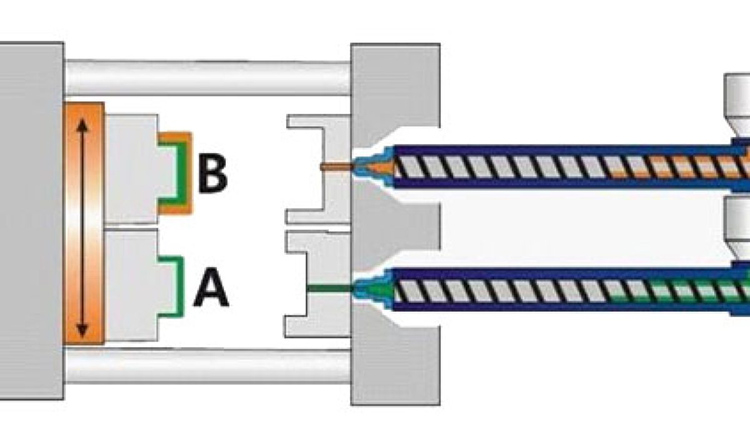

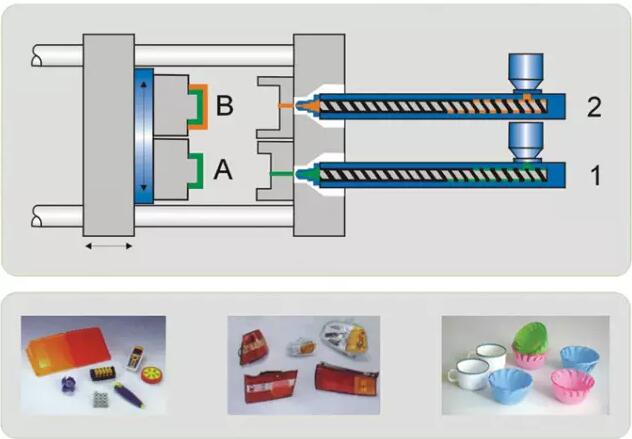

Two-shot injection molding is a process that injects two different plastic materials or different colors of plastic into the same mold in two stages. The process typically involves the following steps:

First Injection Stage: The first type of plastic material is injected into part of the mold cavity, forming the basic shape of the product.

Second Injection Stage: After the first material has solidified, the mold rotates or shifts, and the second material is injected into the remaining part of the mold, forming the two-tone effect.

The key feature of this process is the ability to produce multi-colored or multi-functional plastic products in a single production cycle, enhancing both the product's appearance and its performance.

Advantages of Two-Shot Injection Molding

1. Enhanced Functionality and Aesthetics

Two-shot injection molding allows different materials to be combined, such as using soft, wear-resistant plastics for the outer layer and durable engineering plastics for the interior. This combination not only improves the product’s functionality but also enhances its visual appeal. For instance, the outer casing of home appliances can offer both a comfortable, anti-slip texture and scratch resistance, while automotive interior parts can be both visually appealing and durable.

2. Reduction in Assembly Steps and Increased Production Efficiency

Traditional product designs often require multiple parts to be assembled, while two-shot injection molding can integrate multiple functions into a single product, reducing the need for assembly steps, lowering costs, and improving production efficiency. Furthermore, since the product is molded in one go, the potential for errors and time waste from multiple manufacturing processes is eliminated.

3. Environmental Sustainability

With increasingly strict environmental regulations, many companies are turning to eco-friendly materials, such as PLA (Polylactic Acid) and other biodegradable plastics. Okman Packaging Technology (Shanghai) Co., Ltd. actively researches and uses eco-friendly materials, integrating them into products through two-shot injection molding to not only improve product performance but also meet sustainability requirements.

Applications of Two-Shot Injection Molding

1. Consumer Electronics

In the consumer electronics sector, two-shot injection molding is widely used for producing mobile phone casings, earphones, and other electronic accessories. This process enhances both the aesthetics and durability of these products, offering better protection against scratches, impacts, and wear. Okman Packaging Technology has successfully used two-shot injection molding to produce aesthetically pleasing and high-performance electronic product casings for several well-known brands.

2. Automotive Industry

The automotive industry places high demands on the quality and appearance of its components. Two-shot injection molding is used to produce automotive interior parts, exterior components, control buttons, and dashboards, combining durability with design. Okman Packaging Technology has successfully developed two-shot injection molding solutions for the automotive industry, optimizing material combinations to improve the performance of automotive parts.

3. Home Appliances and Consumer Goods

Home appliance products such as vacuum cleaners, refrigerators, washing machines, as well as everyday consumer goods like water bottles and kitchenware, often use two-shot injection molding to improve user experience. By using different materials or colors in different areas, products can achieve enhanced grip, wear resistance, and visual appeal. Okman Packaging Technology has supplied high-quality two-shot injection molded products in these industries, helping various well-known brands stand out in the market.

4. Medical Devices

Medical devices require high precision and durability, and two-shot injection molding can achieve multiple functions within a single product. For example, different parts of a medical device's outer shell can be made from different materials to enhance antibacterial properties, high-temperature resistance, and more. Okman Packaging Technology has successfully applied its advanced two-shot injection molding technology in the medical field, ensuring the safety and reliability of medical equipment.

Okman Packaging Technology's Expertise in Two-Shot Injection Molding

Okman Packaging Technology (Shanghai) Co., Ltd. is a company specializing in the development of plastic products and molds, dedicated to providing one-stop solutions for plastic injection molding, mold design, and manufacturing. The company boasts a 4,000-square-meter production facility and is equipped with state-of-the-art injection molding equipment. With years of technical expertise and experience in various industries, Okman has achieved significant progress in two-shot injection molding technology, offering the following advantages:

1. Strong R&D Capabilities

Okman has extensive experience in the development of PMMA (Polymethyl Methacrylate) and various engineering plastics, allowing it to provide high-quality, high-performance two-shot injection molding solutions. Whether for standard product designs or customized technical needs, Okman can meet a wide range of client requirements with its advanced R&D capabilities.

2. Precision Mold Design and Manufacturing

Two-shot injection molding requires precise mold design and manufacturing capabilities. Okman’s in-house mold development team can quickly respond to customer needs and provide customized mold designs, ensuring smooth production processes. With precise molds and injection molding equipment, Okman guarantees the quality and accuracy of every product.

3. Application of Eco-Friendly Materials

With the increasing focus on environmental sustainability, Okman Packaging Technology actively researches and utilizes eco-friendly materials such as PLA (Polylactic Acid) and other biodegradable plastics. The company’s two-shot injection molding solutions not only meet environmental standards but also provide customers with sustainable production options.

4. Efficient Production Capacity

Okman is equipped with advanced injection molding equipment that enables efficient and stable production. Through precise production processes and stringent quality control, Okman ensures consistent product quality and timely delivery, meeting customer demands.

Conclusion

Two-shot injection molding is an innovative plastic processing technology that is transforming the design and manufacturing of products across many industries. Okman Packaging Technology (Shanghai) Co., Ltd., with its rich technical expertise, extensive industry experience, and strong R&D capabilities, has successfully provided high-quality two-shot injection molding solutions for numerous industries. If you would like to learn more about two-shot injection molding technology or have any customized requirements, feel free to contact us. Okman is committed to providing professional technical support and services.