In modern manufacturing, mold development is a crucial technical aspect, particularly in the plastic industry, where mold development companies play a vital role. From design to production, the quality and precision of molds directly determine the quality and production efficiency of plastic products. With continuous technological advancements, mold development companies face increasingly higher market demands and more complex technical challenges.

1. The Key Role of Mold Development

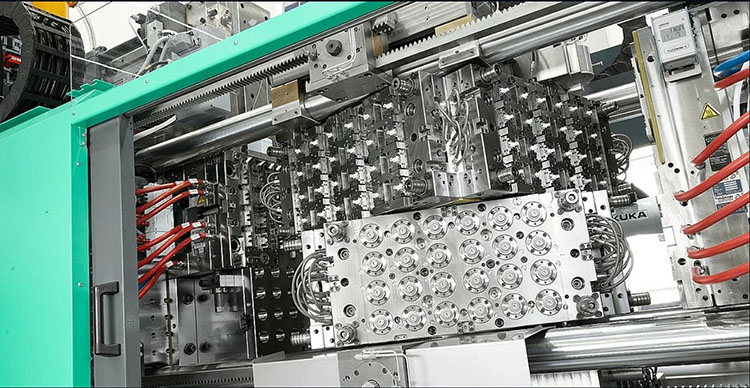

Mold development companies primarily provide customized mold design and production solutions, covering various fields, including injection molds, blow molds, and more. Molds are essential tools in plastic product production, ensuring the shape, dimensional accuracy, and functionality of the final product. Whether for home appliances, automotive components, or consumer goods, the design and manufacturing of molds impact the market performance of the final products.

For example, injection molds are commonly used to produce high-precision, complex plastic components, while blow molds are widely used for manufacturing plastic containers. Mold development companies with expertise in both fields can meet the diverse production needs of various products.

2. Innovative Materials and Environmental Trends

As environmental requirements continue to rise, more and more mold development companies are exploring the application of eco-friendly plastic materials. For instance, PMMA (Polymethyl Methacrylate), known for its high transparency and weather resistance, is widely used in many industries. PLA (Polylactic Acid) and other biodegradable materials are also gradually being adopted in packaging, promoting green manufacturing.

In this field, companies like Okman Packaging Technology (Shanghai) Co., Ltd. have made significant contributions in the application of eco-friendly materials. As a professional mold development company, Okman not only has extensive experience in PMMA and engineering plastics but has also achieved notable success in the application of biodegradable PLA materials, providing clients with green and eco-friendly packaging solutions.

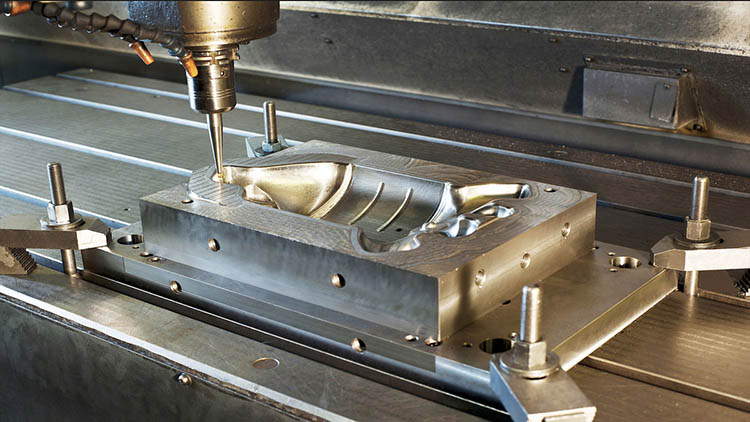

3. Precision and Customization in Mold Design

Mold design requires high precision and customization, especially when dealing with large-scale production. Modern mold development companies typically use advanced tools like CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) to simulate and optimize the mold design process, ensuring the rationality and feasibility of the design. These digital technologies not only enhance the manufacturing precision of molds but also shorten production cycles.

For example, Okman Packaging Technology uses 3D modeling and virtual simulation techniques to customize high-precision molds for clients and, through digital simulations in the design phase, reduces potential problems in production, thereby improving the efficiency and lifespan of molds.

4. Injection Molds vs. Blow Molds: Technological Differences and Applications

Injection and blow molding are two common plastic mold production processes, each with distinct technological characteristics and application areas. Injection molds are suitable for producing precision, small-sized, and complex plastic parts, such as electronic product housings and automotive components. Blow molds, on the other hand, are typically used to manufacture hollow plastic products like bottles and containers, making them ideal for high-volume production.

Okman Packaging Technology (Shanghai) Co., Ltd. has profound expertise in both fields, providing customized solutions for various industries. Whether high-precision and high-strength injection molds or durable, impact-resistant blow molds are needed, Okman can meet the specific needs of clients with professional mold design and production services.

5. Future Trends in the Mold Industry

As technology continues to evolve, the mold industry is undergoing significant changes. Automation, intelligence, and digitalization are becoming the primary trends in future mold production. More and more mold development companies are incorporating robots, intelligent detection systems, and big data analysis to enhance production efficiency and ensure product quality.

Moreover, sustainability has become a critical direction for the future of the mold industry. Green manufacturing and the application of eco-friendly materials are becoming key focuses. Mold development companies must continuously innovate to meet the market demand for environmentally friendly, biodegradable materials while helping clients reduce environmental impact during production.

6. Choosing a Professional Mold Development Company

For businesses, selecting a professional mold development company is not only about acquiring high-quality molds but also receiving comprehensive technical support and services. From mold design and material selection to production debugging, each stage must be carefully controlled. Companies like Okman Packaging Technology (Shanghai) Co., Ltd., with its combined strength in mold development, material research, and post-processing technology, can provide clients with one-stop solutions.

Conclusion

Mold development companies play an increasingly important role in plastic product production. With continuous technological advancements and the growing diversification of market demands, the mold industry is moving toward more precision, efficiency, and environmental sustainability. From traditional injection molds to modern automated production equipment, mold development companies must face challenges while seizing innovation opportunities. Choosing a technologically advanced, service-oriented mold development company is key to improving production capabilities and market competitiveness.